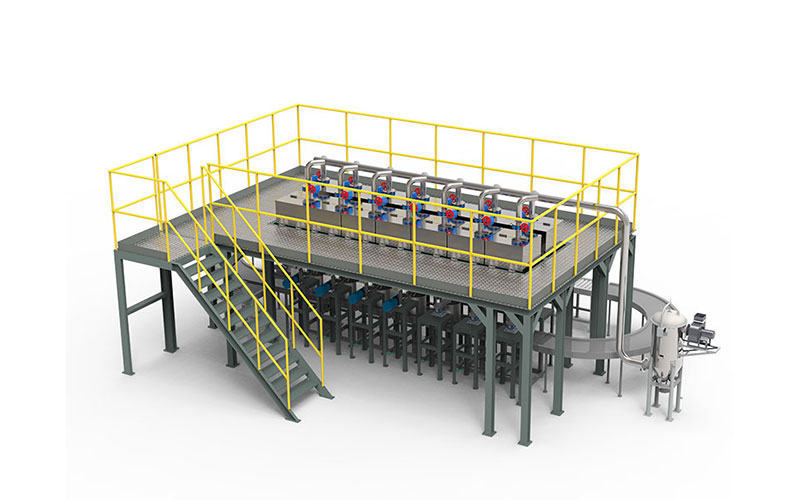

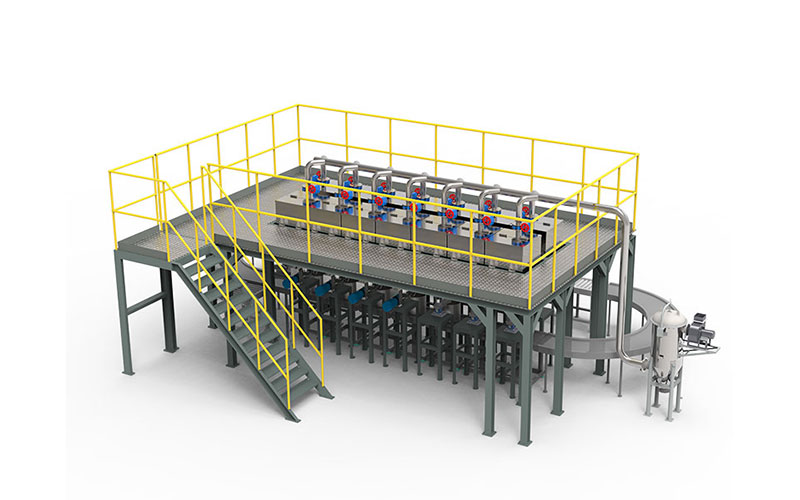

Dosing and batching system

●Function:

Multi-component weighting type Weighing scale

Continuous real-time dosing system

Multi-component vacuum metering system

Automatic measure and batching system for small material

Multi-component weighting type Weighing scale

Composed of a storage bin, high-precision measuring screw conveyor or electromagnetic vibration feeder, measuring scale body and weighing module components, it achieves precise measurement of single or multiple groups of materials.

Continuous real-time dosing system

Consisting of the weightlessness measuring chamber body, weighing device, screw conveyor, pneumatic conveying device, and corresponding control system. The system automatically controls the feeding conveyor screw and speed in real time based on PID regulation to obtain stable, accurate, and continuous feeding quantity, which can achieve continuous quantitative feeding or batch quantitative feeding.

Multi-component vacuum metering system

The multi-component material vacuum metering system consists of a feeding system, a negative pressure conveying system, a vacuum hopper, and a metering system. Only one device is needed to meet the needs of conveying, measuring, and batching various types of powders and granules. Meet the mixing requirements from centralized to distributed, and design targeted according to customer needs.

Automatic measure and batching system for small material

The system mainly consists of a feeding storage bin, a feeding device, a weighing and measuring unit, a conveyor, a dust collector, and a control system. Widely used in the rubber, plastic, chemical and other industries for small and trace material batching, single helix, double helix, electromagnetic vibration feeder and other feeding methods can be adopted according to material characteristics. The entire process is automatically controlled by PLC, which can achieve material management, feeding scanning and error prevention, formula management, and formula barcode printing functions.

Efficient and intelligent material handling

Innovation brings the future.

An optimal material handling system can not only bring great profit margins to customers, increase production, improve efficiency, reduce labor, material, and material consumption costs, but also provide excellent working environment, visiting environment, and industry status for factories, ultimately steadily moving towards a complete intelligent and modern factory

Our vision is to become a global leader in intelligent solid material handling and promote sustainable industrial development through technological innovation

CZL - enables every material to accurately reach the future!

русский

русский Deutsch

Deutsch Français

Français